Blog — Friday, 29 November, 2019

Everyone has been concentrating on their individual tasks. On Monday, Mattis was sanding the hull at the bow. Sanding a vertical surface can be extremely tiring, as anyone who has done it knows.

More and more of the staff are working on interior projects. Shipwrights Kawashima and Tatsumi have spent the last month measuring and installing the paneled bulkheads of the ships cabins, and Hashimoto finished a beautifully detailed section of one cupboard door frame.

Murata has been carefully (he says “nervously”) varnishing the starboard inboard wash-strake, which was made by Richard and Mattis. Paul and the other shipwrights continuously impress the younger workers with how important the varnishing process is.

Lewis has been focusing on sealing the mahogany with the first coats of shellac, to match the repairs on the mahogany furniture to the original color — of course, using as much of the original materials as possible. Color matching of old timber with new is very exacting and time consuming work.

Graham was still working on the teak rudder blade this week. It’s a large and extremely important project, yet he’s still trying to use as much as possible of the original timber while only replacing the damaged sections.

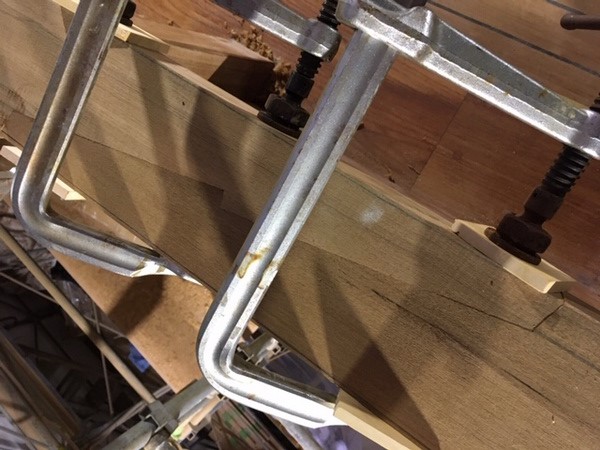

Richard has been working on a technique of clamping complex longitudinal joints together to create an elegant curved continuous capping rails. He was so pleased with the result that he wants to show Mr. Watanabe, the CEO of Riviera, and the owner of Cynara.

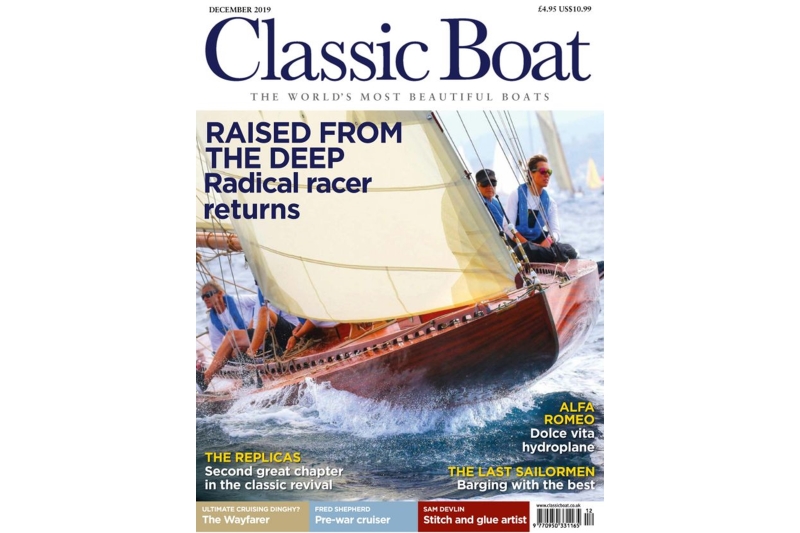

The elegant cupboard door frame made by Hashimoto.

The sweeping curve of the capping rail.

Gluing up Richard’s intricate longitudinal capping rail joint.