Blog — Monday , 30 September, 2019

Tuesday, September 24

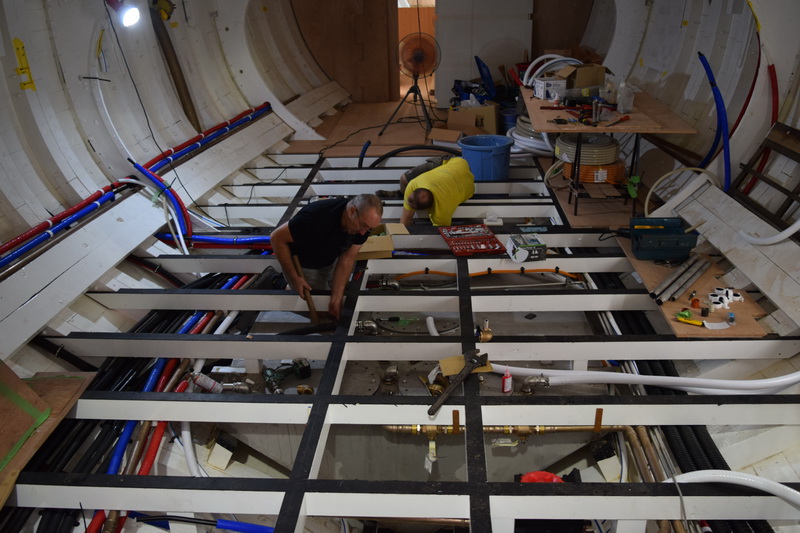

Progress is going smoothly on the deck.

Nico makes patterns for the framework which will create a linen cupboard and hanging locker in the aft guest cabins. The hot and cold water pipes run through and into the engine room.

Carlo uses original furniture and panels to check cabin dimensions.

Wednesday, September 25, 2019

Dust and dirt are fatal to laying down a perfect deck so a lot of effort goes into keeping things clean—sweeping and vacuuming are constant tasks.

Michael is setting out the bulkhead for the crew shower and heads, fixing points on the deck beams which will give him positions for the patterns.

Thursday, September 26

Mattis is fitting the washstrake at the prow.

Tatsumi is working on the engine room companionway. Hashimoto is removing the old shellac to prepare for bulkhead panel restoration.

Friday, September 27, 2019

Things are really moving fast on deck, and the deck team is planning to spend the weekend sightseeing in Tokyo.

Daniel is fitting hardware to the main boom (above), while Japanese team members continue with the varnishing (below).

Monday, September 30, 2019

Matisse is working at the bow.

And Lewis is fitting a piece of wood to finish the lead keel. A sharp point made of lead would be weak, so the lead is finished with a squared end and a timber filler is fitted and faired to the hull.

Paul has been directing a test fit of the original stairs. They need fitting to confirm the heights for the main house floor and benches. Plus, they’re one of the first major parts in, as bulkheads and partitions are built against them. With the stairs in, access to the interior is much improved and work on the interior is picking up.