News & Updates

Published in YACHTING WORLD November 2021

Our project was published in YACHTING WORLD November 2021. Click below for more details. More about this, you can find out here.

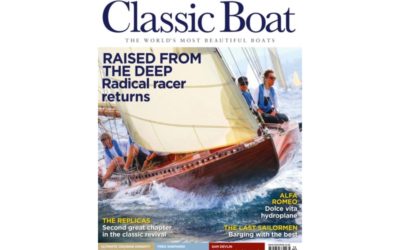

Published in Classic Boat July 2021

Our project was published in Classic Boat July 2021. Click below for more details. More about this, you can find out here.

Cynara featured in the June issue of Classic Boat magazine

The June issue of Classic Boat magazine featured Cynara on the cover and in a 7-page, full-color article. This came after the magazine named the restored boat as the winner of a “Classic Boat Award 2021.” More about this, you can find out here.

Published in Classic Boat MAY 2021

Our project was published in Classic Boat MAY 2021. Click below for more details. More about this, you can find out here.

News — CYNARA Wins “Classic Boat Awards 2021”

CYNARA Wins "Classic Boat Awards 2021"We are proud to announce that CYNARA was named the winner in her category of the Classic Boat Awards 2021. The awards are given by Classic Boat magazine, and the winners were announced at a digital ceremony held on Thursday, April...

Blog — Sunday , 8 March , 2021

March 8, 2021 The inclinometer, barometer and chronometer have been installed in the deckhouse over the steps down to the passageway. The inclinometer was on the boat, though it is likely not from the era of the 1927 launch. It was given a new face and the...

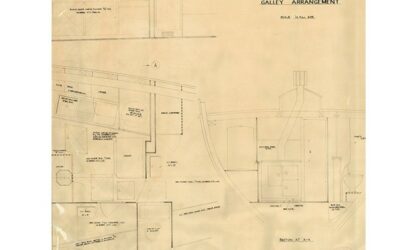

Blog — Sunday , 21 February , 2021

February 21,2021 We received permission from the British National Maritime Museum in Greenwich, London to reproduce (in low resolution) some of the plans, drawn by the Camper & Nicholsons shipyard from the museum’s archives. They come from the time of the launch...

Blog — Friday , 5 February , 2021

February 5, 2021 Everything that could be restored or repaired on Cynara has been used or is now being worked on. But we’ve found ways of recycling parts that were beyond repair or restoration as well. These are the former futtocks from the frame that now are part of...

Blog — Monday , 25 January , 2021

January 25,2021 We’ve shown different steps in building and installing the table in the saloon, and thought we would bring everyone up to date now that it’s done. The table top is in three sections, and is newly made of mahogany after the old table top proved to be...

Blog — Sunday , 17 January , 2021

January 13,2021 Yokokawa, Fujita and Saito were preparing for the next day’s sailing. Wada is teaching crew-member Fujita how to varnish. Build-up coats offer a good opportunity for learning, but it is a skill that takes time to master. The top coats are done...

News — Cynara nominated for “Classic Boat Awards 2021”

Cynara nominated for “Classic Boat Awards 2021”We are pleased to announce that the Riviera-owned classic yacht Cynara has been nominated for the 14th annual Classic Boat Awards 2021 hosted by the British magazine Classic Boat. The awards are held to celebrate the...

Blog — Monday , 11 January , 2021

January 9,2021 Cynara’s doors are all original and are being fitted back into their original frames. As the ship lost its shape over the years, doors sometimes stuck shut or refused to close. Those doors would then be cut or have their edges planed so they would still...

Blog — Thursday , 8 January , 2021

January 4,2021 Kawashima is making final adjustments to the drawers under an aft cabin bunk. Tatsumi and Hashimoto are working together to prepare the original guest cabin doors for refitting. Here they are making a pattern of the frame to check against the...

Blog — Sunday , 27 December , 2020

December 26,2020 Kawashima made this slatted floor for the shower room. Paul is installing the gimballed dining table in the saloon. The base is all original, and has been restored. We desperately wanted to save the original table top, but unfortunately, the...

Blog — Saturday , 21 December , 2020

December 21,2020 Tatsumi is installing latches and handles on the pocket doors that connect the staterooms to the heads. The doors are only 30 millimeters thick, with only a few millimeters of clearance on each side, so the handles were difficult to find. That’s...

Blog — Thursday , 17 December , 2020

December 12 Hashimoto is fitting fiddles on a drawer unit in the starboard guest cabin. Wada is putting another coat of varnish on one of the two deck tables. This is a job saved for rainy days or days when applying finish in Cynara’s interior can’t be done...

Blog — Friday , 11 December , 2020

December 1 Tatsumi is finishing up the linen cupboard in one of the aft guest cabins. Hashimoto is checking an angle with a bevel gauge while making the frames for the galley cabinets. Kawashima is making the cabinet for the captain’s cabin, after the...

Blog — Saturday , 26 November , 2020

November 16 to 23 Kawashima is setting out the hull lining in the captain’s cabin. Before its final fitting, the cables and ducts have to be finished before the hull lining closes them off. Wada and other painting team members are varnishing the inside of the...

Blog — Sunday , 15 November , 2020

November 8 to 15 Kawashima is fitting the desk and drawers in the Captain’s cabin. Tatsumi is making the cabinet above the crew’s washbasin. Hashimoto is making a duct for the air conditioning in the floor of the galley. Kawashima, Hashimoto, and...

Blog — Saturday , 7 November , 2020

November 3 to November 7 Paul and Hirai are discussing the shower ventilation for the showers in the owner’s and guest cabins. We’ve made special ventilation panels, but a box needs to be built to attach the fan ducting to the panels. Hashimoto is making panels...

Blog — Monday , 2 November , 2020

October 27 to November 2 The nickel-plated light switches have been restored and temporarily installed so that the lights can be used during work hours. When everything is done, they’ll be fitted with the correct nickel-plated screws that are less obtrusive. ...

Blog — Sunday , 25 October , 2020

October 12 to 18 There was a hole in a saloon cabinet where a radio was fitted sometime in the past, most likely in the 1950s or 60s. We considered various ideas before deciding to place modern stereo speakers behind this grill (with the same elegant pattern as the...

Blog — Sunday , 11 October , 2020

October 5 to October 11 The fixtures have been installed for the sinks (above) and showers (below). Hashimoto has been cutting holes to install the electric switches. Makoto is stripping and cleaning the old shellac from the door panel moldings....

Blog — Sunday , 4 October , 2020

September 14 to September 20 On the deck, we set up the table to check that everything fit. We’ll cut the legs to the right length accounting for the deck camber. We also checked the position to see how the chairs fit around the hatches. The table is designed to fold...

Published in NHK WORLD JAPAN

Our project was featured in " NHK WORLD JAPAN " for September 18, 2020 More about this, you can find out here.

Blog — Sunday , 13 September, 2020

September 7 to September 13 Kawashima continues to work on the drawers that are going under the main house sole in the starboard guest cabin. There were lockers here (probably from the 1950s), but the original drawings showed drawers. So we took out the lockers and...

Published in TV asahi’s “Minato zikan”

Our project was featured in TV asahi's "Minato zikan" for September 5th, 2020. More about this, you can find out here.

Blog — Tuesday , 25 August, 2020

Wednesday, August 19, 2020 Paul is adjusting the gate on the deck after we found it had expanded in the rain of this record-breaking summer. Kawashima is building the frame and installing the glass of the double skylight over the corridor. This frame allows air...

Blog — Monday , 17 August, 2020

Monday, August 10, 2020 Kawashima is building the framed panels that close off the hull of the ship and create a cabin side. The frame work is all traditional, with the wood joined with mortice, tenons and wedges, exactly like the original ones. Of course, they have...

Blog — Tuesday , 28 July, 2020

Sunday, July 26, 2020 Hashimoto is finishing a cabinet before the shelves are set out and fitted. The varnish on the deckhouse interior looked all the more brilliant today when lit by the rays of the sun. Tuesday, July 28, 2020 ...

Blog — Monday , 20 July, 2020

Sunday, July 19 , 2020 Today was a rare day with moments of sunshine. This year’s rainy season has been ferocious, with many downpours, and few sunny days, so it has been hard to squeeze in work on the deck. Paul took advantage of the weather and taught...

Published in NHK’s “Ohayo Nippon”

Our project was featured in NHK's "Ohayo Nippon" for July 20, 2020. More about this, you can find out here.

Blog — Saturday , 18 July, 2020

July 15, 2020 Above: Tatsumi is repairing the doors of the cupboards in the main saloon, so that they can be assembled following the original design. These cupboards are all original, but the delicate glazing bars were damaged, and need repairing. A...

Blog — Tuesday , 14 July, 2020

July 12, 2020 Today, we had a quick meeting to go over the upcoming schedule. Priorities are made, but we have to juggle jobs depending on the weather and other conditions. Today, the weather was sunny for the first time in a while, and Kawashima, Saito and...

Blog — Tuesday , 7 July, 2020

July 4, 2020 Most of the non-Japanese team members left Japan at the end of last month. The team now consists of Paul leading the Japanese carpenters and Chuck leading the crew in a sail training program. These drawers have come out of storage after being selected for...

Blog — Tuesday , 23 June, 2020

Tuesday, June 9 The day started early, with Paul gathering all the Japanese craftsmen for a progress meeting (below). He covered all the various tasks that need to be done, and made a schedule leading up to the launching ceremony. Murata applies varnish to the...

Blog — Monday , 1 June, 2020

Tuesday, May 26 Prior to the sail tests, Chuck, as head of the rigging team (above), has been going over all the knots and attachments on the masts, booms and sails (below). We’re getting close to the final days of the restoration. Protecting the deck and floors is a...

Blog — Monday , 25 May, 2020

Tuesday, May 19 Nat is reinforcing the main sail (above and below). The plan for setting up the main sail calls for a day with no rain and little wind, so the riggers are watching the weather patterns very closely. Paul is building a hollow panel that will...

Blog — Thursday , 14 May, 2020

Friday, May 8 Ian is assisting with the wiring. It’s a massive job, given all the new equipment that needs electricity, and very time consuming. Chuck and Nat are going back and forth between Cynara and the tent, preparing to attach the boom to the main mast....

Blog — Friday , 1 May, 2020

Bill and Lewis are in the tent, repairing interior fittings. Bill is building a new locker interior for the owner’s stateroom; Lewis is cleaning up the captain’s bunk frame. The mizzen mast boom which was installed yesterday has now been finely adjusted,...

Blog — Tuesday , 28 April, 2020

Work on the interior is a step-by-step process. As Paul said to Mr. Watanabe the other day, the photos that are being taken every day don’t adequately capture the steady progress that is being made. But work is now focused on the main saloon and cabins, including the...

Blog — Friday , 24 April, 2020

It rained all day on Monday the 20th, but that didn’t really slow down the work on the interior, as the shipwrights continued work in the tent and below deck. Generally speaking, one carpenter focuses on one task—bunks, for example, or vents. This way, the work on...

Blog — Thursday , 16 April, 2020

Yesterday, the mast was stepped in perfect conditions: fine weather, flat ocean, and no wind. Over the 90-plus years since she was built, Cynara has hogged considerably, leaving a wave in the sheer line and a real challenge for the naval architect and the shipwrights...

Blog — Tuesday , 14 April, 2020

Last Thursday, we filled Cynara’s tanks with 1000 liters of fuel. The engine and gearbox are what she had before the restoration, though the engine was sent back to Yanmar for a full rebuild. On deck, the case covering the gearbox at the helm was installed. With all...

Blog — Wednesday, 8 April, 2020

Wednesday, April 8, 2020 The state of Cynara has progressed at pace since last Monday, when she was transferred to the water by the big sea crane. We are working on the benches on the left and right side in the doghouse, the rails for the sliding hatches and other...

Blog — Tuesday, 31 March, 2020

Almost 3 years of hard work by Riviera’s team of shipwrights and support staff came to a climax at the end of March, when Cynara was lifted back into the water. Because the team at Riviera had done every facet of the rebuild in-house, including moving her out of her...

Blog — Tuesday, 24 March, 2020

This week, Cynara finally moved out into the sunshine after two years of restoration work inside the tent. On March 15, steel workers began building the cradle to move the 75 tons of Cynara over the fifty meters to the water’s edge. Various ideas for the design of the...

Blog — Tuesday, 17 March, 2020

Nikki Wellings has come from her base in Italy to do all the traditional leatherwork that goes into Cynara’s rigging and other areas. There’s quite a bit that needs to be done, from the gaff saddles on the masts to the holders for the winch handles to the inside of...

Blog — Tuesday, 10 March, 2020

The bronze hawse pipes that the anchor chains and hawsers or heavy mooring lines pass through finally arrived. Richard had created a model from vinyl foam, which was sent to a casting expert in the France who created the bronze parts. Some deliveries of material from...

Blog — Tuesday, 3 March, 2020

Our gilder Julian arrived from Mallorca this week to add the decorative touch of metallic gild to Cynara’s hull. This is a must for any classic yacht, and in its early years, Cynara would have had this done every year or so along with repainting. The metallic gold...

Blog — Tuesday, 25 February, 2020

Sanding and application of the hull’s top coat continued this week—the third and last coat! Nico and Bill were working on the lower scaffold level; Jesper (with a roller) and Paul (with a brush) were in charge of the upper level. The focus of interior work has been on...

Blog — Tuesday, 18 February, 2020

At the beginning of the week, Paul and Ben went over the schedule at a general meeting. Things have been very busy over the last weeks, and that will continue. The changes are much more visible than previously. One day, for example, there is no name on the stern; then...

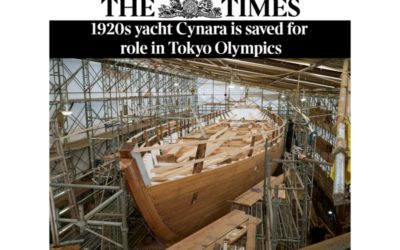

Published in THE TIMES

Our project was published in THE TIMES. Click below for more details. (1) Newspaper (Saturday, February 15, 2020) (2) Digital: Paid Article (Friday, February 14, 2020)

Blog — Tuesday, 11 February, 2020

This week saw the installation of the bowsprit. Billy prepared the block and tackles to get the spar from the ground and into the scaffold, yesterday, and this morning shipwrights Paul and Ben, along with Bill and Chuck the rigger—worked in unison to get it in place,...

Blog — Tuesday, 4 February, 2020

Head rigger Chuck arrived at Seabornia last Friday from the south of France, together with Nat, a rigger from Maine. The riggers’ job is to prepare the deck, the mast, and its fittings for installation, which will take place soon after Cynara is put back in the water....

Blog — Tuesday, 28 January, 2020

Work is still ongoing on deck, but much of the focus has shifted to the interior. The mahogany panels are starting to be installed, and some of the cabin partitions constructed of poplar (as were the originals) have been trial fitted. The original desk from the main...

Blog — Tuesday, 21 January, 2020

After being spray-painted in an elegant dark blue color, chosen by Mr. Watanabe, the mooring bitts, fairleads, and hardware for the bowsprit are being laid out on deck in their various positions. The varnishing team is taking a break from mast varnishing and is now...

Blog — Tuesday, 14 January, 2020

The year 2020 will certainly be one to remember, as this is the year we hope to complete the restoration of the classic English gaff ketch Cynara. The detailing and fine tuning of the many deck fittings is underway. Some team members were making plywood patterns for...

Blog — Friday, 27 December, 2019

Work on Cynara did not slow down at year-end, unlike the rest of Japan. On Monday, Graham was working on attaching the copper sheathing to sections of the rudder. He carefully made thick paper templates of each piece then cut these shapes out of copper sheets. A...

Blog — Friday, 20 December, 2019

Jonathan, a new member of the team arrived from Europe. He left his native NZ in his teens, and has since spent most of is working life working on classic yachts in various locations across Europe. From early Monday morning, five crew members were working on the...

Blog — Friday, 13 December, 2019

Monday saw a full day of wiring installation by the engineers. Work continued on the interior, with the first of the mahogany bulkhead panels installed between the saloon and main cabins, and master shipwrights Paul and Ben carefully checked the original location of...

Blog — Friday, 6 December, 2019

Work on the Cynara’s wiring continues. In most parts of the world, the crews working on boat maintenance—the shipwrights, carpenters, engineers, painters, varnishers, and electricians—usually try to work at staggered times, so that they’re not in each other’s way....

Blog — Friday, 29 November, 2019

Everyone has been concentrating on their individual tasks. On Monday, Mattis was sanding the hull at the bow. Sanding a vertical surface can be extremely tiring, as anyone who has done it knows. More and more of the staff are working on interior projects. Shipwrights...

Published in CLASSIC BOAT for December 2019

Our project was published in CLASSIC BOAT for December 2019. More about this, you can find out here.

Blog — Friday, 22 November, 2019

The storm passed without doing any damage to the tent, and Wednesday dawned calm and clear. Work on the rudder, the rudder shaft and the steering gear continued. By Thursday, installation of the heavy timbers of the stern chock cheeks, where they take on a low and...

Blog — Tuesday, 19 November, 2019

On Monday, forecasts of a storm that night had everyone preparing. But that didn’t stop Mattis and Richard from working on the bow, drilling holes for the hawsepipe and for the bowsprit. The steering gear pedestal was installed before the rudder stock was done, and is...

Blog — Friday,15 November, 2019

The week began, as every week does, with Paul going over the schedule with everyone. He sees everything, and he gives advice to newcomers, even on how to sweep, telling them, “As you sweep, take a good look at what each person is doing.” The hole for the rudder tube...

Blog — Friday, 8 November, 2019

The week was a productive one, with progress made in many areas. Mattis and Richard began the week by trial-fitting the tenon joints on the top of the stanchions, where the capping rails will be attached. Graham continued drilling the hole for the rudder stock tube...

Blog — Wednesday , 30 October, 2019

Tues. Oct. 22 With the deck planking done, we have the entire deck as a workspace. Nico is working on the bowsprit chock, and can now put in temporary place to make sure it fits. It is a sizable piece of wood and is all original. Further back, Richard is...

Blog — Monday , 21 October, 2019

Sun.Oct. 13 Typhoon Hagibis made landfall last night just west of us on the Izu Peninsula. It ended up being one of the largest typhoons ever recorded, with over 200,000 people ordered to evacuate, and the matches for the World Rugby Cup cancelled. It was fairly...

Blog — Thursday , 10 October, 2019

Wed. Oct. 2 As we enter October, the temperature has fallen, which has made life a little easier for the shipwrights. But we’re still in the middle of typhoon season, and Cynara is protected only by a tent. A smaller tent stands adjacent—where work on the interior,...

Blog — Monday , 30 September, 2019

Tuesday, September 24 Progress is going smoothly on the deck. Nico makes patterns for the framework which will create a linen cupboard and hanging locker in the aft guest cabins. The hot and cold water pipes run through and into the engine room. Carlo...

Blog — Monday , 23 September, 2019

Thursday, September 19, 2019 Full-scale restoration of interior fittings has begun. Currently, we have completed some of the procurement of the needed wood material, but we’ll need to make further wood purchases as we discover what is usable and what is necessary....

Blog — Wednesday , 18 September, 2019

Sunday, September 8, 2019 As Typhoon Faxai is approaching, most of the Japanese members of the team were intent on making sure everything was tied down or protected. The tents were lashed down (above) . . . And vulnerable parts on the deck were covered. The...

Project Update Video

A video was created in June 2018 to share the restoration progress. Narrated by Paul Harvey, Master Shipwright. Restoration by RIVIERA GROUP Restoration photos by Yoichi YabeCopyright 2019

Cynara Project Presentation in Cannes

By Invitation Only

Cynara Website has Launched!

Cynara website has launched. Follow the restoration project as it happens! More content coming soon as the project progresses for her launch in Spring 2020.

Blog — Thursday , 7 September, 2019

Monday, September 2, 2019 Ben, Pascal and Ian are discussing the welding plans for the fuel tank. Later on, it started as scheduled with the company Sawamura Tekko handling the welding. It’s expected to take two or three days. Hashimoto is working on finishing...

Blog — Friday , 30 August, 2019

Thursday, August 22 Ben has started drilling holes through the 6mm thick stainless steel of the fuel tank to attach a fuel level sensor and air vents. The cylindrical hatch to the anchor locker is now in the installation stage. Monday, August 26 (Above)...

Blog — Wednesday , 21 August, 2019

Wednesday, August 14 , 2019 The production and installation of the cover boards are proceeding smoothly.Steadily, every day, long teak planks are sawn, adjusted and dry fitted to the ship. Paul and other members of the team are setting out the heights for the...

Blog — Tuesday , 13 August, 2019

Wednesday, August 7 , 2019 Lewis and Richard began sanding the surface of the subdeck. Batons (long straight sticks that bend evenly) are used to check for high and low spots. The floor has been fitted, though some panels will be lifted to access the pipe work...

Blog — Tuesday , 6 August, 2019

Thursday, August 1, 2019 Preparing the interior floor, or sole, which will be laid in two phases. These 19mm plywood panels are cut, fitted and then painted before being installed. The painted side will face down toward the bilge so it can be kept clean and bright....

Blog — Friday , 19 July, 2019

Monday, July 15, 2019 We started preparing for laying the teak deck today. Cleaning the entire inside of the tent and inside the ship. We’ll install the sole, or floor, this week so that we can proceed with the electrical wiring work. We changed the height of...

Blog — Friday , 12 July, 2019

Monday, July 8, 2019 There are two teams—Lewis and Nico, and Richard and Michael—working on the plywood subdeck. They’ve made a table on the deck where they can cut the sheets of plywood. Chuck is also on the deck, making measurements for the masts and rigging....

Blog — Friday , 5 July, 2019

Monday, July 1, 2019 The tanks have been lowered to where they are sitting on the tank bearers in the bilge. Later, stainless steel straps will be used to secure them in place. The deck beams have many bolts, rivets, and fasteners through them, and places that...

Blog — Saturday , 28 June, 2019

Monday, June 24, 2019 Richard, Michael and Kawashima worked on the coverboard. They were very conscious about knots in the wood. Tuesday, June 25, 2019 The production of the cover board around the stanchions and chainplates continues. Chuck and Nat...

Blog — Friday , 21 June, 2019

Monday, June 17, 2019 The tanks have been fabricated of stainless steel and pressure tested. Now they’re ready for installation. Hashimoto has begun production of the circular surround for the sail locker hatch (all the other hatches are square). The plan...

Blog — Friday , 14 June, 2019

Monday, June 10, 2019 Chuck began work today, as did his assistant Nat. Paul and Ben brought them up to speed on the restoration. The seams between the planks are being cleaned before being painted with a primer. The propeller also arrived today. It has...

Blog — Friday , 7 June, 2019

Monday, June 3, 2019 Ben is leading the last-minute preparations for the interior lead ballast loading that will take place tomorrow. The area was painted, and Ben shaved the lead bit by bit in order to make the shape of the lead fit perfectly. There’s a story...

Blog — Friday , 31 May, 2019

Thursday, May 23, 2019 Richard and Lewis are fairing the beams to make sure they are all level with each other and follow the curve of the deck as they should. The dust was flying, so everyone was wearing masks today. We discussed the upcoming schedule for the...

Blog — Wednesday , 22 May, 2019

Wednesday, May 15, 2019 Fitting carlings and partners. Makoto is cutting off the teak bungs flush with the hull planking. Fairing the planking at the counter, the overhanging part of the stern. We heard that the masts recently left the UK and are...

Blog — Monday , 13 May, 2019

Tuesday, May 7, 2019 Leo and Ian are fitting the hanging and lodging knees into the hull. Paul is making a copy of the ship’s numbers. He took a rubbing to get a completely authentic copy, including any original quirks. The Japanese members of the team...

Blog — Monday , 6 May, 2019

Wednesday, May 1, 2019 Lewis fitting one of the deck beams, dovetailing one of the ends into the beam shelf. The wood stanchions are being set out in order, ready for their first fit. Inside the tent where the interior work is being done, Kawashima and...

Blog — Tuesday , 30 April, 2019

Tuesday, April 23, 2019 It’s only April, but inside the tent it is hot enough to feel like summer. Lewis and Richard are continuing work on the deck beams. Checking out the keel before bringing the ballast in for installation. Ben had removed the end of...

Blog — Monday , 22 April, 2019

Monday, April 15, 2019 It is time to start preparing for reattaching the ballast to the keel. Above, some of the blocking that elevated the keel over the H-beam strong back is being removed to allow access to the underside of the keel. Paul, Daniel and Demetri...

Blog – March , 2019

March 1-8 The teak skylight of the main saloon looks battered and worn but after a closer inspection the piece is not in bad condition considering its age. This was true for all of the deck skylights, hatches and companionways. This is a testament to both teak, as a...

Blog – February , 2019

January 1-8 , 2019 Makoto is cutting bungs flush with the hull planks. All in, there are thousands of bungs that all need to be cut, fitted and finished one by one. The freshly painted bilge. Hopefully this coat will be more successful than the first. Battens are...

Blog – January , 2019

January 7-15 , 2019 Above, Mattis prepares to cut one of the new sheer planks. Cynara’s teak planking was in remarkably good condition for a yacht of her size and age, with the high-quality teak withstanding most of the hardships of a life at sea for almost a century....

Blog — December , 2018

December 1-8, 2018 Now that the skylight bases have been assembled, Hashimoto is turning his attention to the frames for the glass. The frames had been originally assembled using natural products like linseed oil and red lead, so they were easy to take apart. We clean...

Blog — November, 2018

November 1-4 , 2018 In order to replicate the finish of the interior mahogany-panelled bulkheads a small selection of panels were removed from various areas of the frames in various states of condition and sent to a lab in Letterfrack, a small village in Ireland....

Blog — October 2018

October 1-15 , 2018 Kawashima is working on a plank that has had a new end scarphed and glued on. The scarphs are placed over a frame so that mechanical fasteners can be used through the joint into the frame. This ensures that should the glue ever fail, there would be...

Blog — September , 2018

September 10-17, 2018 Some of the approximately 5 tons of lead ballast (above) that was removed from Cynara’s bilge. Internal ballast would be redistributed later to account for the new systems, the tanks and machinery layout. As the planking work makes its way...

Blog — August 27-September 2 , 2018

August 27-Sep 2 , 2018 With the new horn timber section in place the transoms can now be fitted. Only the lower half of the transoms have been laminated at this stage, so these are being checked in their positions against the timber ribbands fitted on the hull. ...

Blog — August 13-19 , 2018

August 13-19 , 2018 Richard makes minor adjustments to one of the housings or ‘boxes’ in the new stem section that will take the new frame foot. Mattis starts to fit single frames in the counter stern. It’s difficult to see here but the centerpiece of the hull...

Blog — August 1-5 , 2018

August 1-5 , 2018 Lewis’s shaft boring project is progressing steadily. A pilot hole has been drilled and now the boring bar is set up to cut progressively larger diameters at an oblique angle through the chock. An electric drill drives the cutter as a brass...

Blog — July 23-29 , 2018

July 2018 , 23-29 Ben kerfs the stem with a chainsaw (above). This is part of the nosing, the second part of the stem repair, which will create the point and leading edge that is seen on the outside of the stem forward of the plank ends. Kerfing, which is cutting a...

Blog — July 16-22 , 2018

July 2018 , 16-22 Teli drills the holes in the throat of the floors needed for the hold down bolts. The hold down bolts will fasten the floors on the keel timber. The bolts’ unusual square heads allow for the bolts to be tightened even when the ballast is in place....

Blog — July 9-15 , 2018

July 2018 , 9-15 Pairs of frames for the stem area are ready to be beveled and fitted. The last two frames in the stern are not actually frames at all—each one is usually cut from a single piece of oak encompassing the deck beam and the hull shape into a single...

Blog — July 1-8 , 2018

July 2018 , 1-8 Hashimoto (above) is working on a plan to fill in an old fitting. The planks like this that have large holes from old skin fittings (valves and ports that pass through the planks) need patching. His patching is taking shape (below). The planks from...

Blog — June 25-30 , 2018

June 25 to June 30 , 2018 Another strake is fitted, with the rivets and dumps hammered home by our newest recruit, Mattis Voss (above). He is a German-born Irishman and a highly skilled shipwright. Hashimoto is helping with the fastening when a strake is...

Blog — June 18-24 , 2018

June 18 to June 24 , 2018 Lewis does some final shaping of the shaft log and cuts housings for the frames. Once the planks are fitted and we’re satisfied, bungs are glued into the holes left by rivet and nail heads. We have used glue but the originals were dry...

Blog — June 11-17 , 2018

June 11 to June 17 , 2018 As soon as the yacht was lifted from the water, we noticed that something strange had happened to the after end of the ballast keel. The usual method to connect the ballast to any deadwood or false keels is a large scarph joint securely...

Blog — June 6-10 , 2018

June 6 to June 10 , 2018 A few words on Cynara’s planking. It is “edge set,” which means that relatively straight planks can be cut with fair edges and gently bent sideways into position. The amount of edge set changes depending on where the plank is to fit. This...

Blog — June 1-3 , 2018

June 1 to June 3 , 2018 The stem lamination has been moved from the joinery tent to the main build tent, which has more space and is closer to its final destination. It’s heavy, so the closer to the boat, the better. The frame housings are being cut into the...

Blog — May 21-27 , 2018

May 21 to May 27, 2018 The deck house panels with the portholes have been removed, revealing more information on their past. We’re still investigating the deck house’s original appearance. It’s time to give the new stem it’s first dry fit, to fill the gaping...

Blog — May 13-19 , 2018

May 13 to 19 English shipwright Jonathan Alcock started this week and got to work on restoring the main deck house. He is a talented designer, a great asset for a joiner. The skylights on the side of the deck house were not original and were probably added in...

Blog — May 7-13 , 2018

May 7 to May 13, 2018 The first stage of the lamination of the stem . . . . . . and more layers as the process continues. Paul and Keiji are checking the fairness of the frames where they are boxed into the stem. We used ribbands and stiff batons to fair...

Blog — May 1-5 , 2018

May 1 to May 5, 2018 These large pieces of iroko have been re-sawn at Matsui, a local lumber mill for use in the new stem section. Ben is starting the laminating process for the stem section using the iroko with staggered scarph joints. Keiji Kawashima...

Blog — April , 2018

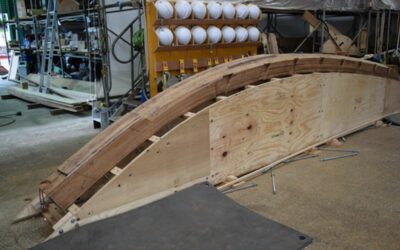

April, 2018 The laminates for the deck beams are being rough cut on our bandsaw (above). The timber is heavy and awkward to manipulate even after it is resawn into manageable sizes. The laminates are stacked in our drying shed. A very few of the...

Blog — March 26-30, 2018

March 26-30,2018 Once the deck beam laminates were sufficiently dry, they could be machined to size before being set aside to rest the exposed fresh timber. These (above) are almost ready to laminate. The laminates have to be dry before final machining to get them...

Blog — March 19-25, 2018

March 19-25,2018 One of the laminated frames, ready for its bevels. Pascal (above) grinds the head from a rivet. The bung hole is thoroughly cleared, and care is taken when the rivet is driven out not to damage the edge of the hole on the exterior of the plank....

Blog — March 12-18, 2018

March 12-18,2018 Nico drills for the naval brass drift that will be used at the base of each futtock as Richard guides the drill angle. Enough frame pairs are ready and faired to begin fastening them permanently into their sockets. The frames are bedded in red lead...

Blog — February, 2018

February, 2018 Planks that have been damaged or have unwanted fastener holes are bunged, and a teak patch is glued over the top to restore the surface. Lewis, Hashimoto, and Kawashima discuss the process of cutting out the futtocks. The riveted steel...

Blog — January, 2018

January, 2018 Carefully selected strakes, which are a run of planks from the stem to stern, are being removed by extracting the rivets and the ship nails (called dumps) with slide hammers and drifts. Kawashima (above) is drilling a hole into the head of a dump....

Blog — December , 2017

December, 2017 This month saw the removal, packing and shipping of a number of items to be repaired, restored, or used as models for making new versions, when that was necessary. The bronze quadrant, which is part of the steering mechanism (above), the...

Blog — November , 2017

November 2017 The plan to remove the ballast and straighten the boat moved ahead. It included the making of two heavy duty tables that would support the boat fore and aft. The tables (forward one above) were designed to support the strong back carrying the hull and...

Blog — October , 2017

October 2017 The keel bolts were removed, cleaned and measured. Of the 18 keel bolts, only three of the main ones and two smaller ones at the stem ended up being replaced, even though some were slightly bent. They were sent for inspection using a dye which shows any...

Blog — September , 2017

September 2017 We continued cataloguing and storing items from the interior. The ingenuity of this folding sink (above and below) was fascinating. It is now displayed in the ship’s museum on the Seabornia Marina site. The remains of the beautiful nickel plating on...

Blog — August , 2017

August 2017 In early summer, we began planning the removal of the keel in order to straighten the hog. As we began removing the planks, we found evidence of work that had been done earlier. At some point over the years, the lower half of the stem had been...

Blog — July , 2017

July 2017 Most of the month of July was spent with more dismantling of the interior. By the end of the first week, the interior was largely empty, as can be seen in this view forward from the aft cabin on the port side. The bulkhead in the distance marks the forward...

Blog — June , 2017

June, 2017 This month Cynara was moved into the purpose-built shed for her restoration. She was jacked up on a cradle and railway tracks were built (above) that ran from her location approximately 90 meters across the marina into the shed. It took about one week to...

Blog — January to May , 2017

January, 2017 The proposal by the British shipwrights was accepted by Riviera CEO Noboru Watanabe. On January 23, Cynara was lifted from the bay waters off Seabornia Marina and placed on the dock in preparation for her restoration. May 2017 The shipwrights...

Blog — November, December, 2016

November, December, 2016 In 2016, the ketch Cynara had reached the remarkable age of 89. Although she had a number of refits, fixes and “upgrades” over the years, she was definitely showing it. Though she was still afloat, she hadn’t sailed in some years. ...