Blog — Sunday , 21 February , 2021

February 21,2021

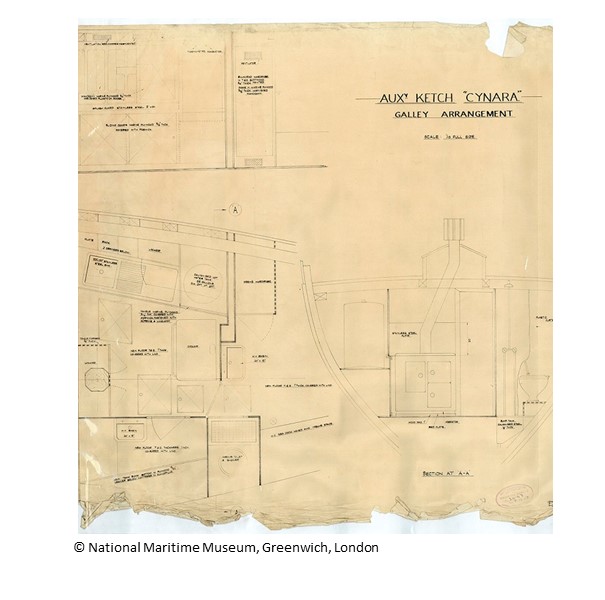

We received permission from the British National Maritime Museum in Greenwich, London to reproduce (in low resolution) some of the plans, drawn by the Camper & Nicholsons shipyard from the museum’s archives. They come from the time of the launch in 1927 and from when Cynara was refitted at various times over the years (including proposals). We found this one that illustrates something we wrote about in an earlier post. These are the plans for the galley, from 1957 and the right half shows the placement of the cooking stove with the chimney rising at an angle before making its way through the skylight. The center piece of the skylight had to be wide enough for the chimney to pass through, so it was larger than the other skylights. The new cooking range doesn’t need a chimney, of course, but as the skylight was in good condition, we kept it as is.

Above is Hashimoto in the process of making the corners of the fiddles for the galley countertop. Cynara’s galley is on the port side, which some sailors believe to be the preferred side. It’s true that a port galley is preferable on a starboard tack, since a cook would find it easier to be leaning over his work rather than having to work uphill. But the opposite is true on a port tack, so the argument is probably moot.

Crew members being educated in keeping the winches in good condition.

While we’re on the topic of winches in good condition, this is the windlass before restoration. Despite its aged appearance, it was fitted in Japan in 1995, and built by Ideal Windlass based in East Greenwich, Rhode Island in the US. We had it restored by Deep Blue Engineering, in Cornwall, UK, and we’re happy with the result (below).

Kawashima has finished the cabinet and the shelf in the Captain’s cabin (above) and is now working on the drawers and doors under the bunk (below).

Saito climbed the last to touch up some of the varnish and took a short break to shoot Cynara from above.

Paul is fitting the bench seats with lockers in the crew’s quarters (above). He’s now turning his attention to the benches themselves, as he’s planing the bench tops to fair the beveled edge (below).

Pascal polished the stainless steel trim that will make up the splash back now being installed around the galley counter (below).

More of the washroom fixtures have been installed, including the soap dishes and toothbrush holders. Like the other fixtures, they are made by Lefroy Brooks the manufacturer of classic British bathrooms. Everything is hand cast, hand forged, hand polished and assembled.

February 18,2021

Sail Training

Weather: Fair

Wind: 6-16 knots, West, West-southwest

Waves: 1.5-1.8 meters

Destination: Zushi