Blog — Tuesday , 28 April, 2020

Work on the interior is a step-by-step process. As Paul said to Mr. Watanabe the other day, the photos that are being taken every day don’t adequately capture the steady progress that is being made. But work is now focused on the main saloon and cabins, including the floorboards, sofas, ceiling, etc. Mattis is working on the sofa in the main salon and is beginning to concentrate on the details, such as the storage space below and behind the sofa.

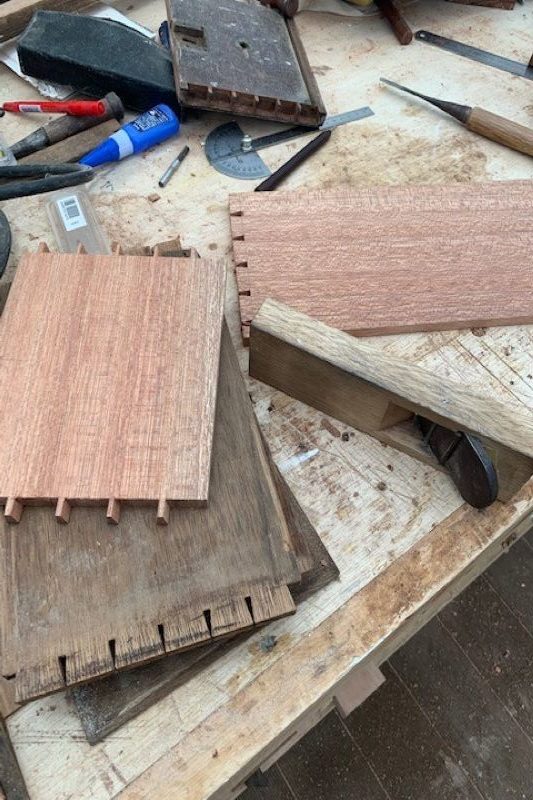

Richard is installing the soleboards without gaps, using a fine-grained Japanese oak variety selected by Mr. Watanabe. Since the length of the floorboards in each part of the boat is different, we measure the length needed for each plank, and make adjustments on site.

The bunk frame was found to have soaked up a lot of oil from when the bilges were full of oily water. It had soaked through the sole and into the bases of the furniture, especially at the aft end of the boat. We had to try and remove the oil and return the furniture to a condition for storing clothing. All of the original bunk frame is being used, and in the second photo above, Lewis is using some chemicals to remove oil and old varnish.

The varnish work on deck continues. Due to dust and the risk of someone putting a hand on wet varnish, varnishing and woodworking cannot be done in the same place at the same time. (Chuck and the rigging team were working in the tent yesterday, giving the varnish team the opportunity to varnish undisturbed by loose ropes and rig gear. Today, both parties worked on deck in close quarters, taking care not to interfere with each other.

The boom was installed on the mizzen mast today. Due to its smaller size, Chuck and Nat were able to manhandle it into place. Next comes the mizzen gaff before fitting the mizzen sail.The main mast boom will be installed after that, followed by the main gaff and the main sail.Thanks to the two main halyards on each mast and the powerful electric deck winches, all these booms can be fitted without having to call in a crane.

Hashimoto is repairing a chest of drawers. The top, drawers and frame are all original. The left side panel of pine had to be replaced, and the panel seen in the photo had to be newly created, as it used to sit next to a sink unit.

Mattis is working on the sofa while Murata is painting the area behind. Pascal is working on the wiring.