June 1 to June 3 , 2018

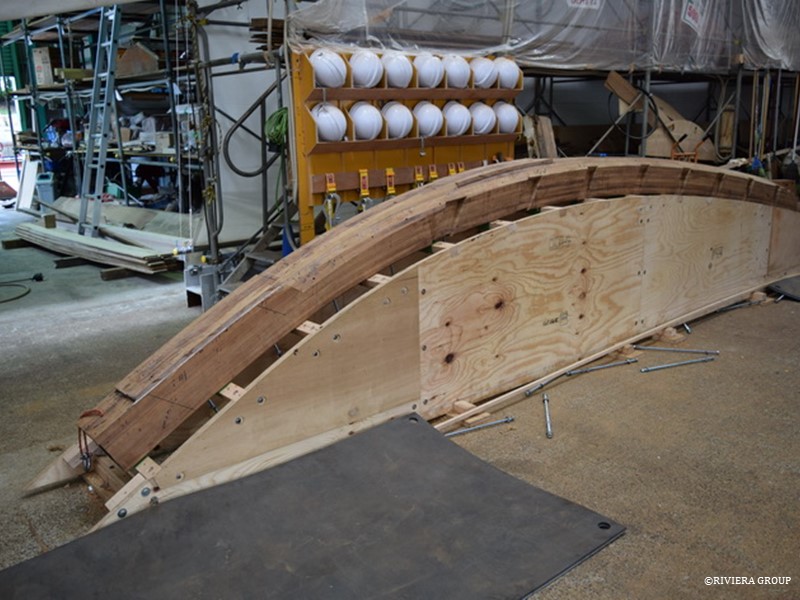

The stem lamination has been moved from the joinery tent to the main build tent, which has more space and is closer to its final destination. It’s heavy, so the closer to the boat, the better.

The frame housings are being cut into the stem to take the frame ends. Each one is different as the angles change along the length, but they must be cut symmetrically. It is critical to cut them in the correct position, so the final shape of each frame will match the corresponding station on our lines drawing.

The crew companionway is being dismantled. This is only possible because, like with other structures, no glue was used in its construction—only tenons, pegs, and a lead-based sealant.

The main deck house side panels are being stripped of their finishes, with care taken not to damage the teak. The house has scars from years of service, but we don’t need any fresh ones.

The dovetails (above) found at the end of the hatch bases are in good condition for their age—not perfect, but serviceable. We’ll use modern glue to patch in any missing parts, but not on the dovetails themselves. A naval brass rod is passed through the center of the joint to add rigidity and stop the joint opening. The diamond-shaped patch is from a fitting that had water damage and will be reinstated when the base is finished.

The shaft log which sits at the junction between the stern post head and the forward end of the horn timber that forms the backbone of the counter stern is out now and placed on the workshop floor. It’s a complicated piece cut from one large piece of oak. We don’t have such a large piece in stock so Lewis will have to fabricate it from several pieces of iroko (below).

The shape has been finalized, but Lewis still needs to drill the offset propeller shaft, while missing the rudder tube which passes through its center.