Blog — Tuesday, 19 November, 2019

On Monday, forecasts of a storm that night had everyone preparing. But that didn’t stop Mattis and Richard from working on the bow, drilling holes for the hawsepipe and for the bowsprit. The steering gear pedestal was installed before the rudder stock was done, and is now ready to be connected to the rudder shaft.

Lewis was working on the mahogany interior paneling, using his professional skills to work out the complex shapes of the panels and other interior fixtures with Tatsumi.

Graham and Paul started to assemble the rudder shaft and steering gear today. It took some precision work to interconnect all the almost 100-year-old bronze parts of the original (which have been serviced with a new gear cut) to achieve silky smooth rotation with no binding. As with other parts of the boat, as much as possible of the original materials were being used. In this case, we almost achieved the magic 100 percent reuse figure.

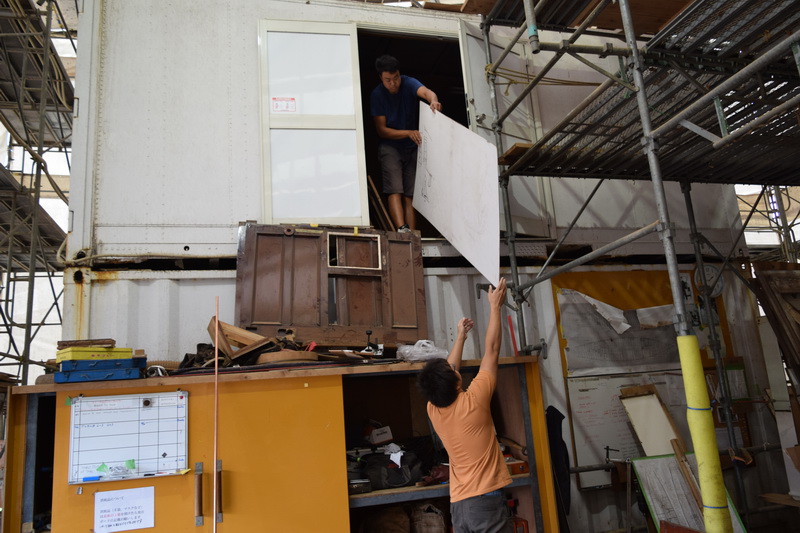

The electrical engineers, Reece and Daniel, carried on 12 batteries and installed them below.

And a government ships inspector came by to do a pre-test of the airtightness of Cynara’s brand new steel engine bulkhead. Some leaks were discovered and will be fixed by the time of the actual inspection.

Beautifully restored bowsprit chock.

Graham fitting the steering bevel gear onto its shaft.