July 2018 , 16-22

Teli drills the holes in the throat of the floors needed for the hold down bolts. The hold down bolts will fasten the floors on the keel timber. The bolts’ unusual square heads allow for the bolts to be tightened even when the ballast is in place.

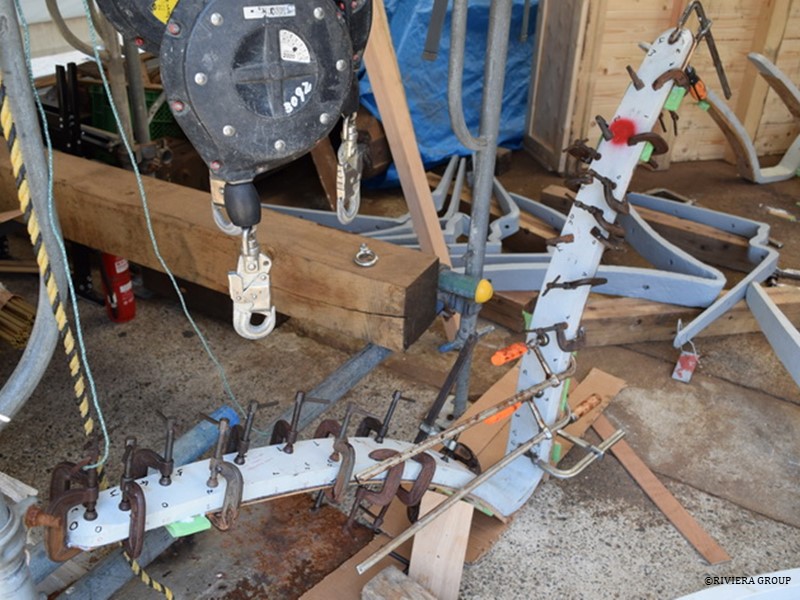

Richard (above) is working with Mattis through each station that carries a floor, checking the fit and marking the rivet holes. The floors are held with 5/8-inch copper rivets right through the frame and plank, and the rivets must miss the plank fastenings and leave enough room at the head for a clean bung. The clips that carry the keel bolts are also being test fitted (below).

Above, Lewis adjusts a channel in the filler piece in the skeg that is part of the shaft log. The channel houses the rudder tube in the block and the block fills a space above the shaft log and the hull. The block is in two halves and is riveted together so that it can be fitted after the rudder tube is in place.

The boring jig (above) for drilling the shaft log takes shape. The holes will guide the pilot drill keeping the center at the correct angle in relation to the timber.

Lewis’s jig (above) is ready for the boring bar. The boring bar is a long, threaded bar with a high-speed steel cutter attached. This is steadily driven through the log (below), adjusting the depth of cut each time.

Lewis has finished drilling the pilot hole (above), just big enough for the boring bar to pass through.

Wada uses a heat gun to soften the glue residue around bungs and repairs. This makes cleaning the planks easier. The epoxy is harder than the surrounding wood and sanding the epoxy runs the risk of sanding away the surrounding wood.