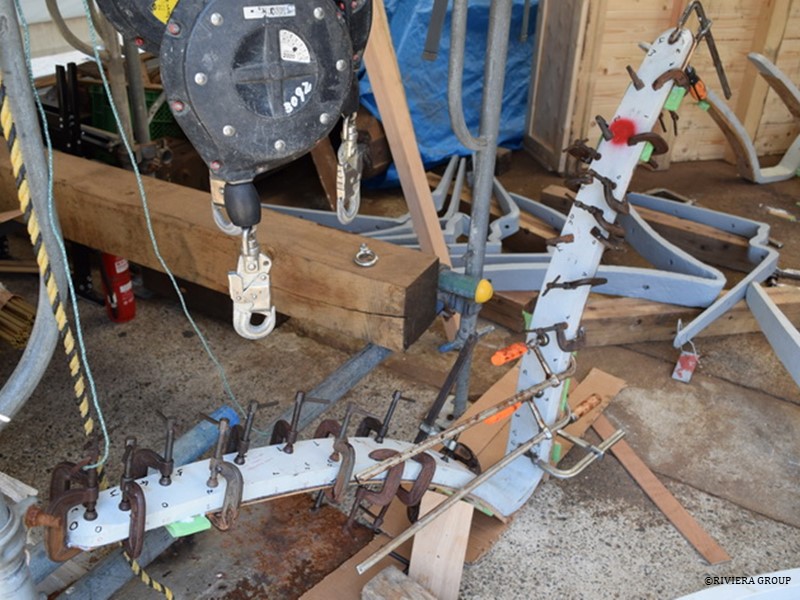

Pairs of frames for the stem area are ready to be beveled and fitted.

The last two frames in the stern are not actually frames at all—each one is usually cut from a single piece of oak encompassing the deck beam and the hull shape into a single piece called a transom. We have laminated ours and the first one starts to take shape (above). Holes are cut for ventilation and access.

Diamond-shaped graving pieces (above and below) are housed into hatch bases that have been damaged from water ingress. Diamond shapes are pleasing to the eye and less noticeable. A joint along the grain is less prominent than a joint across the grain.

The new wrought iron floors forged by Topp & Co (UK), and coated in epoxy paint, have arrived. They took the shape from the original floors that we sent them, and are being tested in place by Nico and Mattis (below).

If there is a gap between the back of the floor and the frame, oak is epoxied to the back of the arm of the floor and the oak is shaped to fit the frame (above).

Thicker pieces are used because they bend easily and are easier to glue (above). By the time they are shaped and fitted, however, there will be very little left (below).