A few words on Cynara’s planking. It is “edge set,” which means that relatively straight planks can be cut with fair edges and gently bent sideways into position. The amount of edge set changes depending on where the plank is to fit. This saves lumber and speeds up the cutting process. We were lucky to have salvaged the majority of Cynara’s 2-inch teak planking, but the planks still need bending into position. We made oak clamps that bolt around the frames next to the plank and then the planks are forced into position with wedges, achieving a tight seam.

The short section of new wood (above) is a graving piece to repair a gouge in the plank surface. In the photo it looks like a short plank, but it is actually about 30% of the plank’s thickness. We’ve been able to salvage planks that might have been discarded in the past thanks to effective glues. Teak is a rare and valuable resource and we don’t want to discard planks just because of minor defects.

If one of the 28-foot-long planks has nothing more than a damaged end (above), a new piece is scarphed on. Scarphs are cut to a ratio and we make sure they fall on frames, so that a mechanical fastening can be used to back up the glue. If the glue fails for any reason, a rivet and a nail or two will stop the plank from springing.

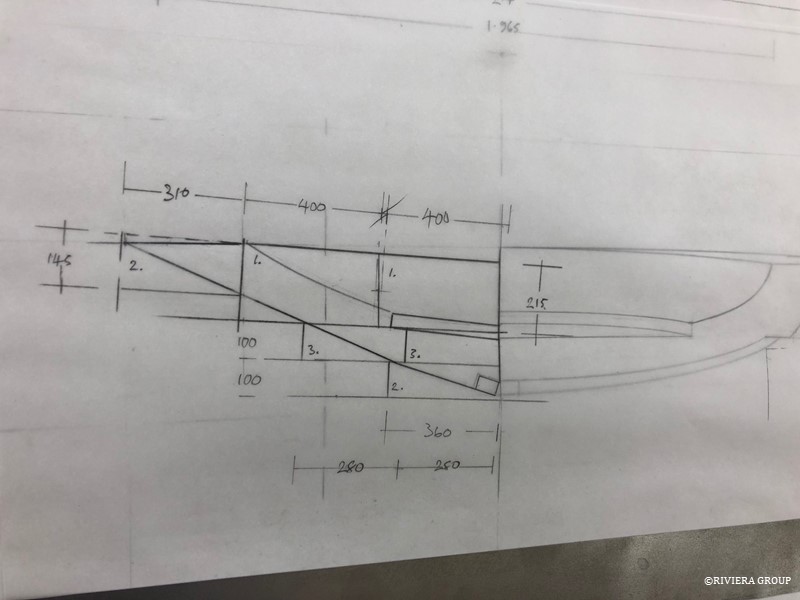

The stern chock is being studied and Paul is collecting data before making a new one (above and below).

The original stern chock was made from two pieces of teak. Pieces of this size are not available today unless sourced directly from the forest. We did find some possible candidates, but the cost was prohibitive. We produced a drawing showing an option for building from smaller pieces, which still are fairly large and quite expensive. Because of the shape of the chock, there will be a lot of waste, but we decided to go with a process that would result in the least amount of lost teak. In this layout, only one joint will be visible, in the same position as on the original chock.

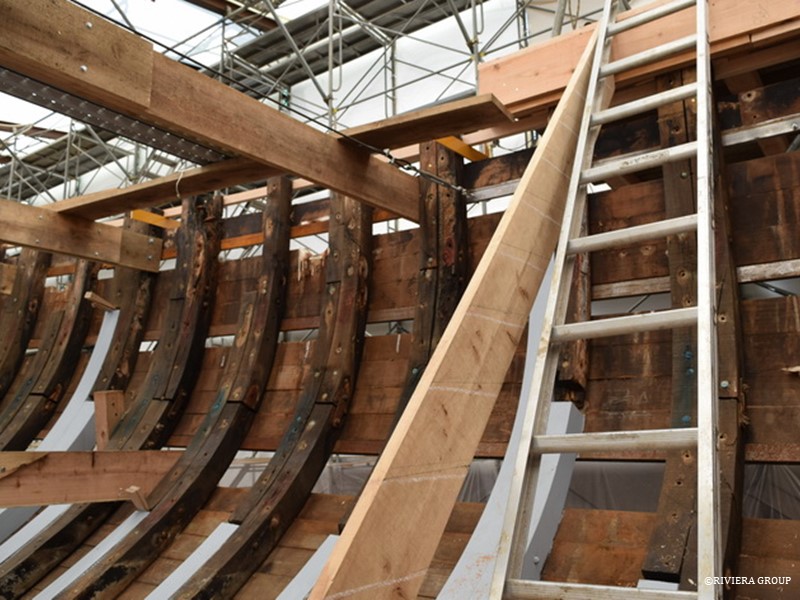

While work on the interior has been continuing, it has been largely inaccessible to visitors. A temporary platform and stairway is being built for an upcoming event (above and below).