Wednesday, August 14 , 2019

The production and installation of the cover boards are proceeding smoothly.

Steadily, every day, long teak planks are sawn, adjusted and dry fitted to the ship.

Paul and other members of the team are setting out the heights for the main house sole, or floor. This has to be done carefully, as we will be using the original parts and the stairway.

Thursday, August 15 , 2019

Ian continues his piping work, which means working in the tightest corners and conditions.

Hashimoto continues his work on the cylindrical hatch. The new one will replicate the original, which was badly cracked, but without its iron fastenings.

Cleaning up the joins on the main deckhouse.

Ben continues to split his time between working on attaching the hardware to the mast and checking the condition of the engine system.

Friday, August 16 , 2019

The same three craftsmen continue with making the cover boards. All the teak planks have now been used.

Monday, August 19 , 2019

Work on the stairs (above) and the skylight (below) is ongoing, but varnish is being applied to keep it clean prior to installation. We’re in what is usually the hottest part of the summer but the days have cooled off a little. Some of the team were able to escape work over the weekend and enjoy a fireworks festival held nearby.

Tuesday, August 20 , 2019

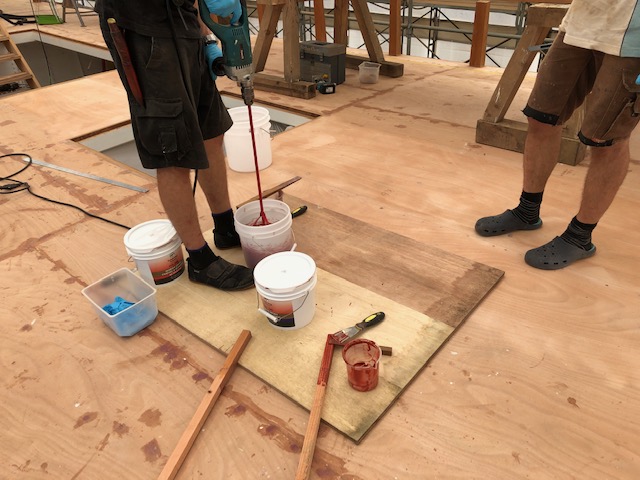

(Above) Glue is mixed and spread along the deck edge to bond the cover board to the sub deck. This glue alone would be strong enough but we are also using bronze wood screws as this is the best way to hold the teak while the glue cures.

Hashimoto is stripping old shellac from a door frame with alcohol.

Wednesday, August 21 , 2019

The coverboard is bonded to the sub-deck. Taping the stanchions helps keep the glue away from them as they will be varnished and dried glue will be difficult to remove.

Today, Lewis, Mattis and Richard are fitting the coverboards over the stanchions….

epair work on the interior fittings varies in size and materials. When new materials are necessary, teak is replaced with teak, mahogany with mahogany and poplar with poplar.