Blog — Tuesday , 13 August, 2019

Wednesday, August 7 , 2019

Lewis and Richard began sanding the surface of the subdeck. Batons (long straight sticks that bend evenly) are used to check for high and low spots.

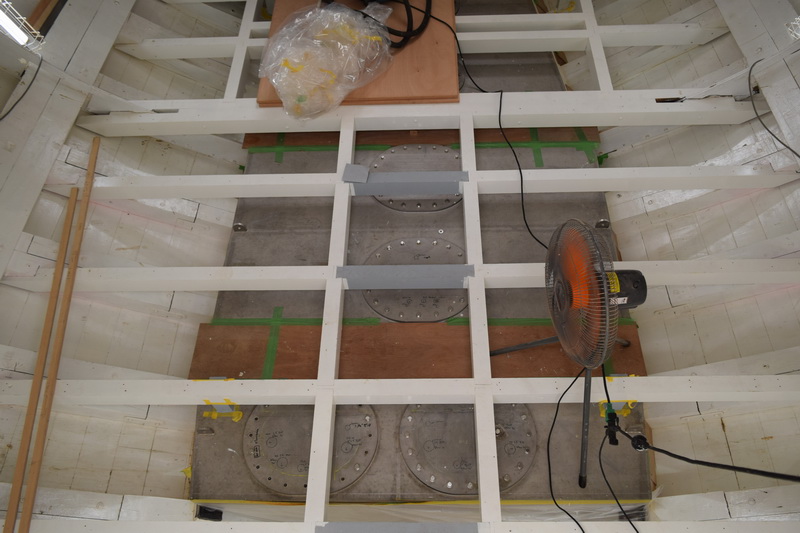

The floor has been fitted, though some panels will be lifted to access the pipe work when necessary. Stairs have been installed (below), which has improved access to the interior.

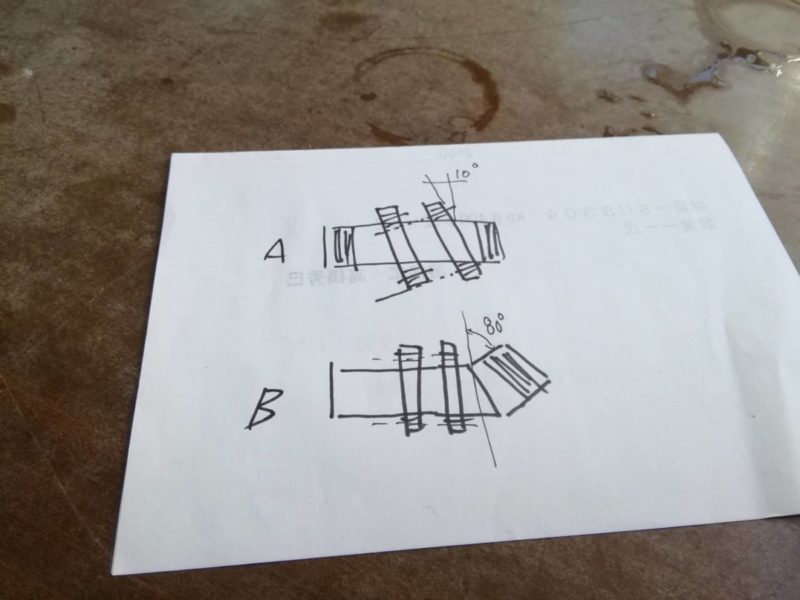

Chuck and Nat are winding the wire for the standing rigging. Chuck says that after 3 days, he needs a day spent on other work in order for his fingers to recover.

Monday August 12, 2019

The holes from the screws used to attach the subdeck were filled with epoxy this morning. After all the surfaces are smooth and even, the teak deck will be installed.

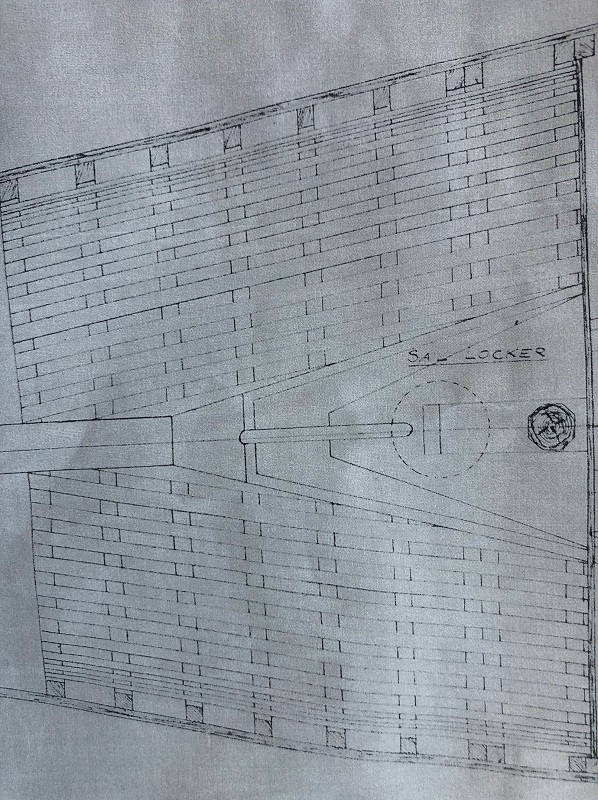

All the exposed edges of plywood, such as that for the circular sail locker hatch (top) are lined with teak which is epoxied in place. This prevents water penetrating into the end grain of the plywood. Plywood’s weakness is that water will travel in all directions as the grain in each layer of the plywood alternates at 90º.

Tuesday, August 13 , 2019

Lewis, Richard, and Mattis are working on the coverboards. The teak for the coverboards is a valuable piece of wood about 7 meters long that was purchased last year, and Paul has been planning to use it for this since then.

Ian is working on the piping under the floor.

More interior walls, which are not in bad shape for their 90 years of age, but not quite good enough for restoration.