Blog — Monday , 1 June, 2020

Tuesday, May 26

Prior to the sail tests, Chuck, as head of the rigging team (above), has been going over all the knots and attachments on the masts, booms and sails (below).

We’re getting close to the final days of the restoration. Protecting the deck and floors is a paramount concern. The mats are changed periodically to make sure nothing is trapped underneath that might scratch or dent the surface. The floor covers and furniture protection will not be removed until everything is completely finished. Everyone has to remove their shoes to keep the interior clean. Louis and John (top) have been among those working on the mahogany interior paneling.

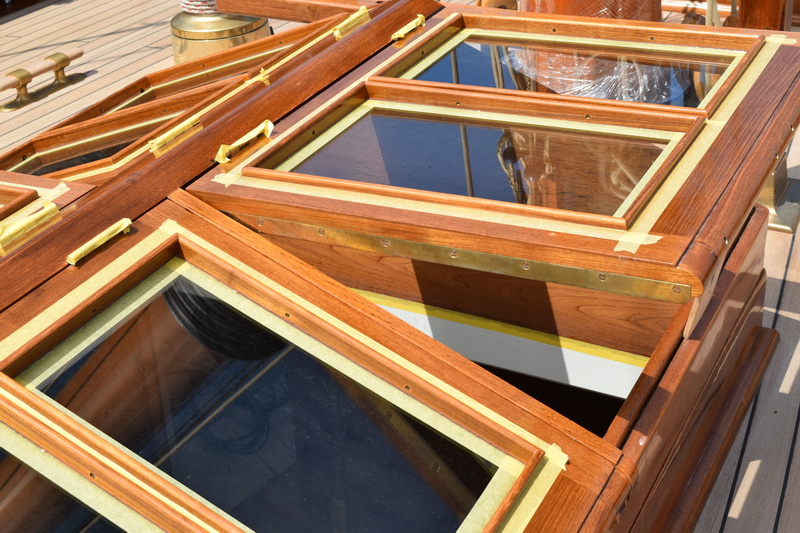

Paul is explaining to the hatch cover maker the system that holds the covers on. We’re using the original system that involves a threaded plate fitted to the hatch with a knurled screw through holes in the covers.

Nat is cleaning the winch button rings, which prevent activating a winch by accidentally stepping on the buttons. This could be extremely dangerous if the winch is under load.

A mock-up of the mizzen boom scissor crutch in the workroom tent. The finished crutch will be placed under the mizzen boom to support and secure it and the gaff when not in use.

Wednesday, May 27

Mattis is working on a new dresser unit (top and middle) that will be used in one of the guest cabins. The original was missing, so this had to be newly made. The drawers (above) belong to another unit that goes in the owner’s cabin. These, along with the rest of the unit, are all original.

In the galley, the electrical wiring is being installed, and the frame for the stove is in the building process. The stove uses a gimbal so it will be able to tilt with the movement of the boat. The frame shown here is a mock-up of the stove unit to make sure the tilting action will have enough space to swing.

Nat is working on all the details that go into the running rigging and main stays. Just as with the woodwork, the detail, all done by hand, is astonishing.

Saito is polishing Cynara’s metal parts. Keeping the parts clean and well-oiled is part of the maintenance that Japanese members of the team are learning to keep Cynara ship-shape for years to come. It is a constant and never-ending job.

Thursday, May 28

Billy is preparing the anchor locker in the prow, where the chain will be stored when the anchor isup. He’s lining the locker with rubber to protect the wood from the heavy chain.

Monday, June 1

Chuck and Nat do a lot of preparation before each step of installing the rigging.

Richard is doing the inboard framing of the portholes.

The anchor chains consist of two lengths of 115 meters each. Saito is attaching markers at 10-meter intervals prior to loading them on Cynara.